Compared with traditional buildings, steel structure buildings have a shorter construction period, are cost-effective, and offer fast construction, eco-friendliness, attractive design, high strength, and excellent seismic performance. All these advantages make steel structure buildings a prominent direction for future development.

You can see the presence of steel structures in various buildings, such as large shopping malls, logistics warehouses, factory workshops, cold storage facilities, livestock farms, schools, hospitals, and residential areas.

If you also want to build such a durable and beautiful building with steel structure please contact us:( Email: consultant7@hglsgroup.com , Phone: 0086-19398195396 ) We will issue drawings for you free of charge and quickly.

Greatly save the construction time, construction is not affected by the seasons

Increase residential space usage, and reduce construction waste and pollution

Reusing construction materials can drive growth in new building materials industries

Good seismic performance, easy to remodel, flexible, convenient, and comfortable

High strength, lightweight, safe, and cost-effective

Aligns with sustainability goals: low carbon, green, eco-friendly, and energy-efficient

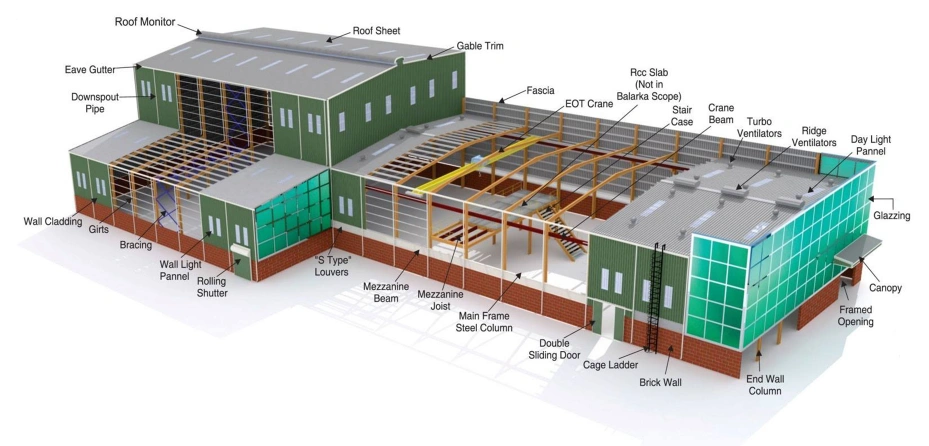

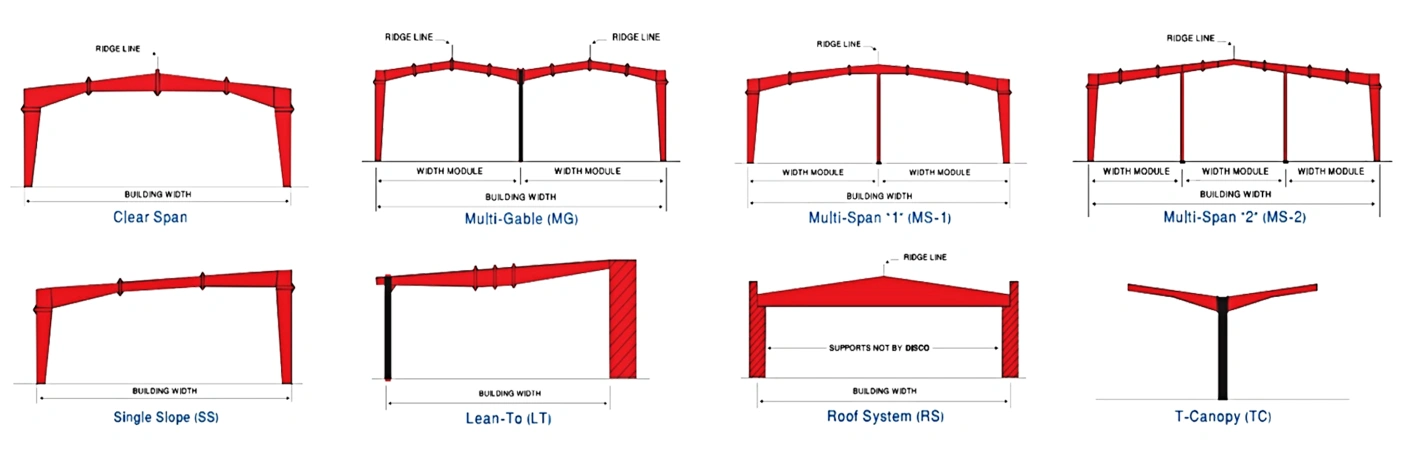

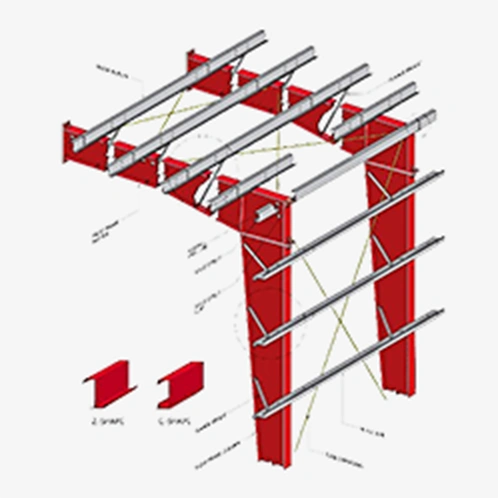

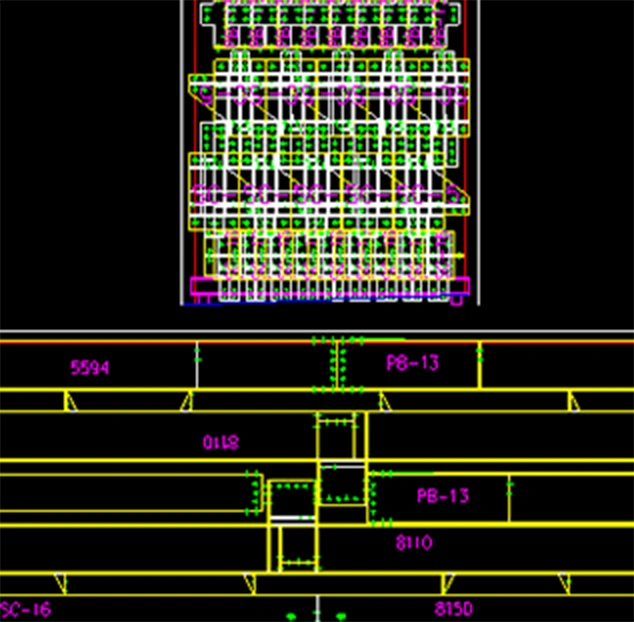

Primary frames are the main load-bearing steel components and can be clear-span rigid frames, continuous beam frames, or post-and-beam frames. They are designed according to the Chinese steel construction manual or any country specific design.

Depending on the building's function, size, and aesthetic requirements, different frame types can be used.

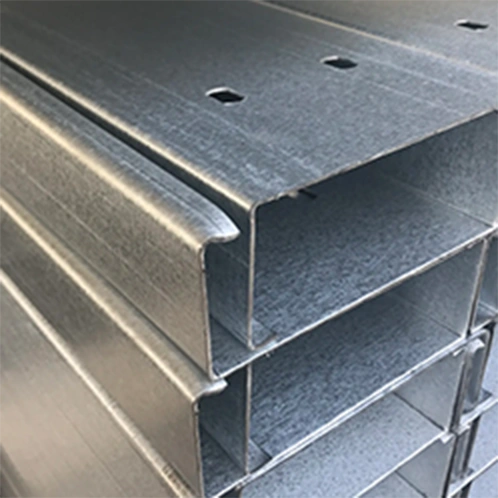

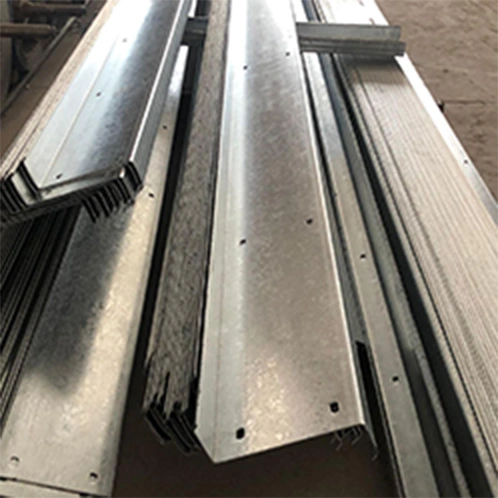

Secondary Supporting Framing is the structural which carry loads to the primary framing members

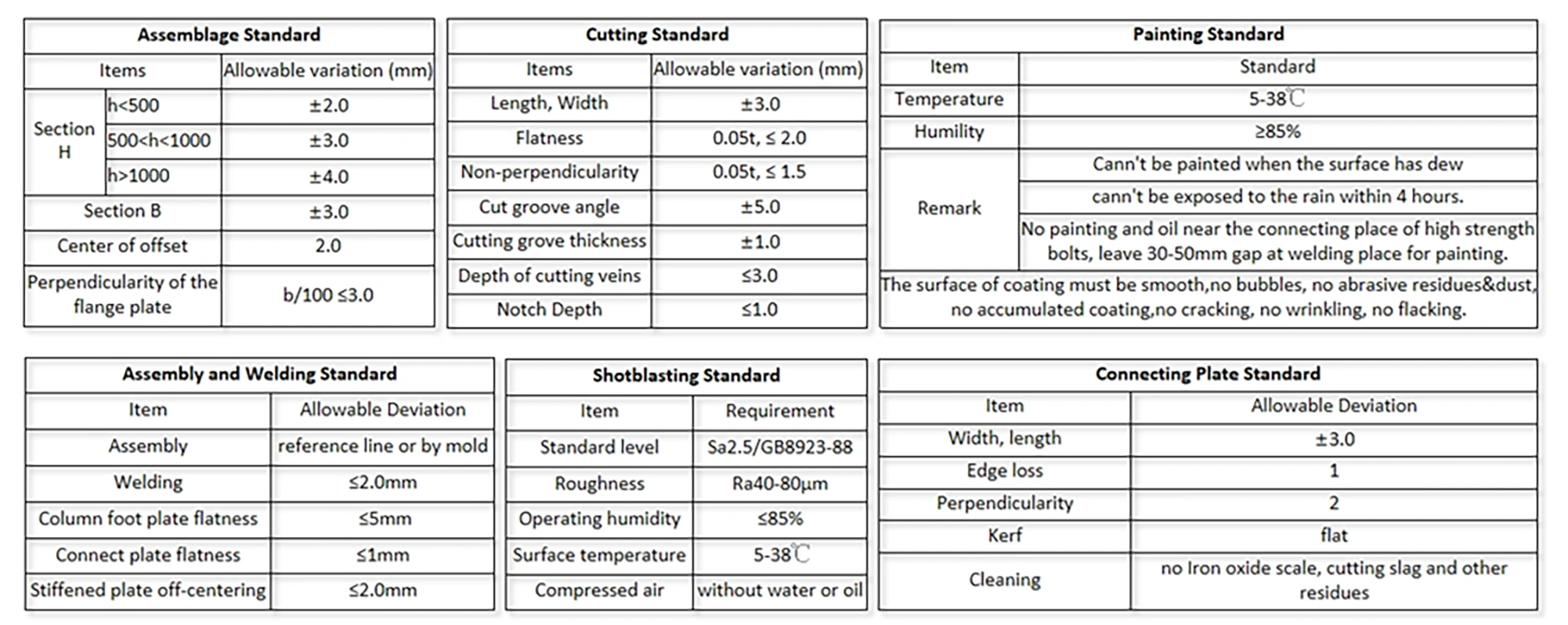

The anti-corrosion performance of a steel structure mainly depends on the quality of shot blasting and anti-rust treatment applied to its surface

Shot blasting derusting class Sa 2 1/2

Paint Treatment: 2 layer anti-rust paint & 1 layer surface paint, thickness above 90um. Anti-rust paint can choose: Alkyd paint,Epoxy zinc-rich paint

Hot Dipped Galvanzied treatment, Zinc coated above 220~250g/m3. above 90u

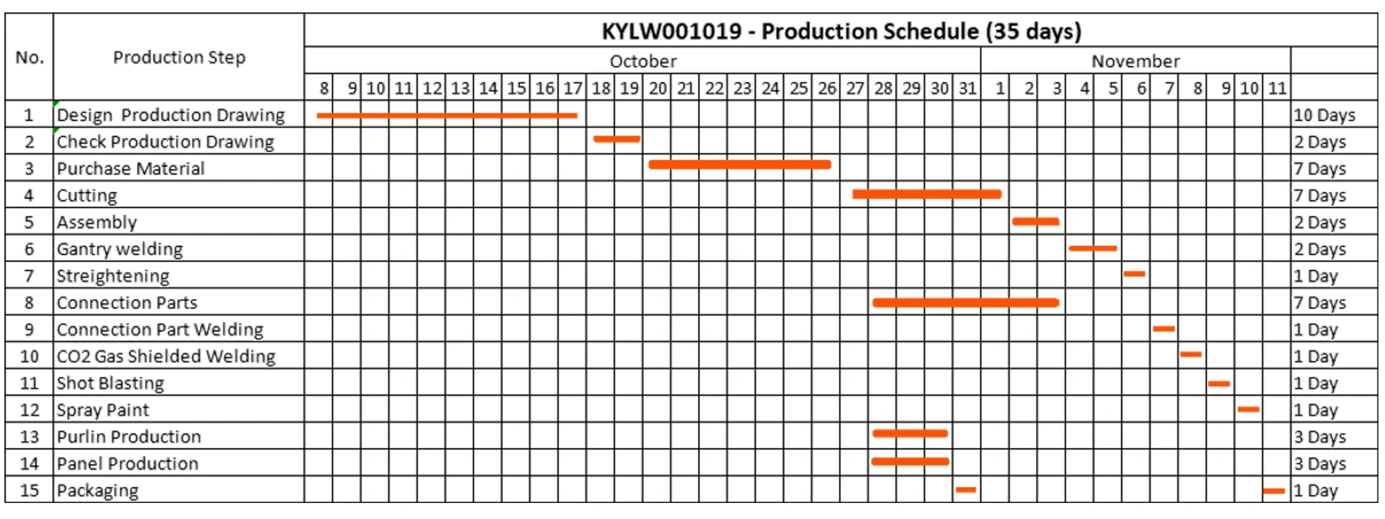

Standard Production Progress to ensure high efficient and accurate production

Production drawing

CNC cutting

Assembly

Gantry Welding

Streightening

Connection parts Production

Connection parts assembly

Gas metal arc welding

Shot blasting

Painting

Panel production

Purlin production

Inspection

Package

Loading

A professional purchasing team with over 10 years of experience, familiar with all types of raw materials

Select the best supplier for each order base on samples, quality standard and contract

Our expert quality inspection team thoroughly checks every part, hole, and weld to ensure durability, stability, and aesthetics. We also welcome third-party inspections, such as those by SGS and BV, and invite customer inspections at any time

Processes: Self-inspection-Worker mutual Inspection-Workshop inspection-Quality inspection department check

The total production time for one building is approximately 35-40 days, with expedited service available for on-time delivery

Ensures the safety of your goods.

Professional packing plans are formulated by the production department upon completion of production.

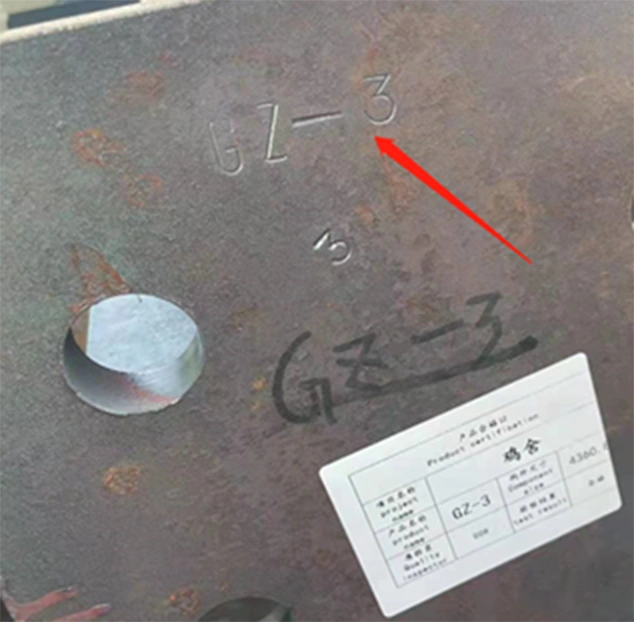

Goods are coded to match installation drawings for quick setup.

Goods are packed on steel pallets, secured with angle steel, and are firm, eco-friendly, and reusable.

Place cushion parts between layers to protect goods from damage or paint scraping.

Make full use of container space.

Make sure it's easy to unload.

Professional Packing Plan

Marked Code

Main structure Pallets

Panels Pallets

How can HENGON build a steel structure building for you?

We guarantee that the steel building will last at least 50 years under normal conditions.

We will resolve any quality or quantity issues for free within 1 year.

We provide technical consulting services throughout the building's lifespan.

Our logistics team monitors the status of goods to ensure smooth delivery.

Our engineering team will provide a detailed list of goods, installation guidance, drawings, documents, and an installation video.

If necessary, engineers can visit the site to guide the installation.

Our after-sales team will follow up on the installation process to ensure successful completion.

All complaints will be addressed within 24 hours.

If you encounter any technical or product issues during the build process, please contact us!

We will provide you with a satisfactory solution!(Email: consultant7@hglsgroup.com , Phone: 0086-19398195396)

A steel warehouse building is a new type of structural system. The main steel frame consists of columns and beams, while the secondary structure is made from C/Z sections, angles, and round tubes. The closed structure includes walls and a roof, along with doors and windows. It is characterized by a large span, high strength, light weight, and flexible arrangement.

Steel structures used as livestock houses are characterized by light weight, high strength, strong corrosion resistance and fast construction speed. During installation, they can provide greater space utilization, good ventilation conditions, high durability and earthquake resistance. Be used for chicken shed, cow shed, swine shed, sheep shed, etc. We do customization of your projects based on local climatic conditions and your specific needs.

Steel structure gas stations combine modern design with industrial strength, offering a durable, safe, and cost-effective solution. Typically constructed with lightweight yet extremely robust steel, these stations ensure structural stability while their open design allows for quick and convenient construction processes. Moreover, the flexibility of steel structures means they can be customized to meet specific needs, enabling efficient operation whether in remote areas or urban centers.

Steel structure used as water tower is characterized by light weight, high strength, strong corrosion resistance and fast construction speed. With high durability and earthquake resistance. We do customization of your water tower based on local climatic conditions and your specific needs, can be any height and loading of water tank.Which is commonly used in industry, agriculture and urban water supply.